About the Company

Manufacturers & Exporters of Knitted, Woven & Wool Garments

MANUFACTURER OF COLLEGIATE PRODUCTS

With 80 initial employees when it was founded in 2005, “Pranao International,” eventually grew to employ over 500 people in entirety.

We began working with the American market in 2007 and have since expanded to include the Australian and European markets.

our company can provide all the needs of our customer with our very own printing and embroidery unit, a flexible stitching unit, a fabric treatment unit (washing) with fabric dyeing, and a circular and flat knitting unit.

Infrastructure

We have built a cutting-edge infrastructure unit where all business operations are carried out safely and effectively. A team of skilled individuals lead the unit and act as the foundation of our business. We have been able to meet the quantitative and qualitative demands of our clients located across the Indian Subcontinent, Europe, the USA, Australia and many other locations thanks to the help of these specialists and a well-developed infrastructure unit.

We are guided through the intricate customs system in the nation by our customs specialist. At the dock’s entrance and departure, our products are subjected to quality control inspections. Our skilled technical professionals assist in promptly and effectively clearing the cargo at the port. To make sure that each cargo is handled appropriately, we have professionals on staff. We try our best to ensure that the shipments arrive at their intended locations on schedule and in good condition.

Knitting

With the aid of our cutting-edge infrastructure and a skilled team of employees, we provide a wide variety of knit finishes and structures. We stay current with the newest fashion trends thanks to our research and development programme, which enables regular changes in our knitting unit.To ensure the quality of the fabric we make, the fabrics are put through a testing process to examine the colour shading, colour fastness, symmetry, size fitting, adhesive checks, and fabric weight.

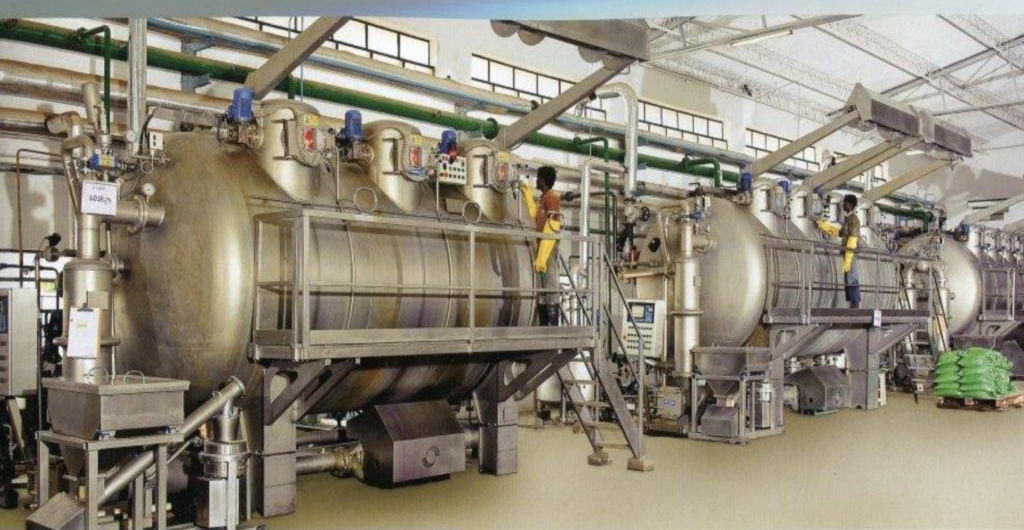

Dyeing

To guarantee exceptional colour accuracy across all of our dyeing procedures, we have implemented a number of contemporary methods. Our dyingplant is capable of producing over 20tones per day with our machine capacity ranging from 50kgs vessels to 1500kg vessel.

We carefully combine our dyestuffs to ensure that they satisfy the following standards: Oeko-Tex-100 GOTS (Global Organic Textile Standard), ZDHC (Zero Discharge Hazardous Chemicals), and Detox to Zero by Oeko-Tex-Standards.

Additionally, our dyeing plant is supported by an Effluent Treatment Plant (ETP) and a Waste Water Recovery Plant with Reverse Osmosis Technology (Zero Liquid Discharge Plant (ZLD)), as we want to lead our industry in implementing the most environmentally friendly methods.

Cutting

Innovative ideas and styles are created in our well-equipped laboratory using the most recent CAD technology. The most current and fashionable patterns for these clothing are created using Gerber pattern-making tools. This course also makes use of machines for digitising and grading. By employing the cloth-laying machinery in this area to prepare the garment for cutting, we ensure the design and quality are in line with the highest international standards.

Printing

Examples of printing patterns used in our unit include flock, pigment, digital, and discharge. To suit the demands of our clients, MHM8 and 12 colour print machines with high resolution are being used.When it comes to fabrics, printing is one of the technologies that changes the most regularly. However, our research and development staff keeps a close watch on all the newest fashion trends and aids us in staying current with global standards.

Embroidery

Embroidering Machines from Barudan, Japan. With a total of three machines, with a combined capacity of 8 lakh stitches per day, these are perfect for adding that extra touch of elegance to the products.

Stitching

For the majority of people who are eager to work in the apparel manufacturing sector, we are their primary employer. Our personnel receives rapid upskilling training to keep up with the most recent trends in every department. Our manufacturing facilities are outfitted with machinery that is operated by skilled staff from all parts of India.

OUR MOTO

Performing with responsibility to serve the industry better High Quality Commitment and Delivery Schedule in Time and Continual improvements with Innovations catering to the International Standards.

Contact Information

Address: D.No.2/298, 11 – Chettipalayam, Poondi Ring Road, Angeripalayam (PO), Tiruppur – 641603, Tamil Nadu – India

Phone: +91 99943 55332

Email: jai@pranaointl.com